Transformer Health Assessment

Our Services

Transformer Health Assessment

Generally, the transformer has a life expectancy of 30 years or more. However, sometimes the power/Distribution transformer failure may occur faster because of degradation under the combination of thermal, electrical, chemical, mechanical and environmental stresses. While the transformer is operating, it is experiencing things that accelerate ageing, such as water content, temperature and oxidation. Therefore, transformer health assessment has to be done periodically to anticipate the sudden failure of active parts.

Transformer insulation failure can be caused by several factors, some of them are fault factor, oil quality factor, and paper condition factor. Those three factors have a major effect on the transformer insulation system.

The healthiness of transformer insulation and it’s accessories to be checked/ tested periodically to avoid sudden failure.

We do the following steps to ensure the healthiness of transformer

Visual Inspection

- Inspect for oil leaks, corrosion, loose connections, and physical damage.

- Check the condition of bushings, gaskets, and external components.

- Verify proper grounding and earthing connections.

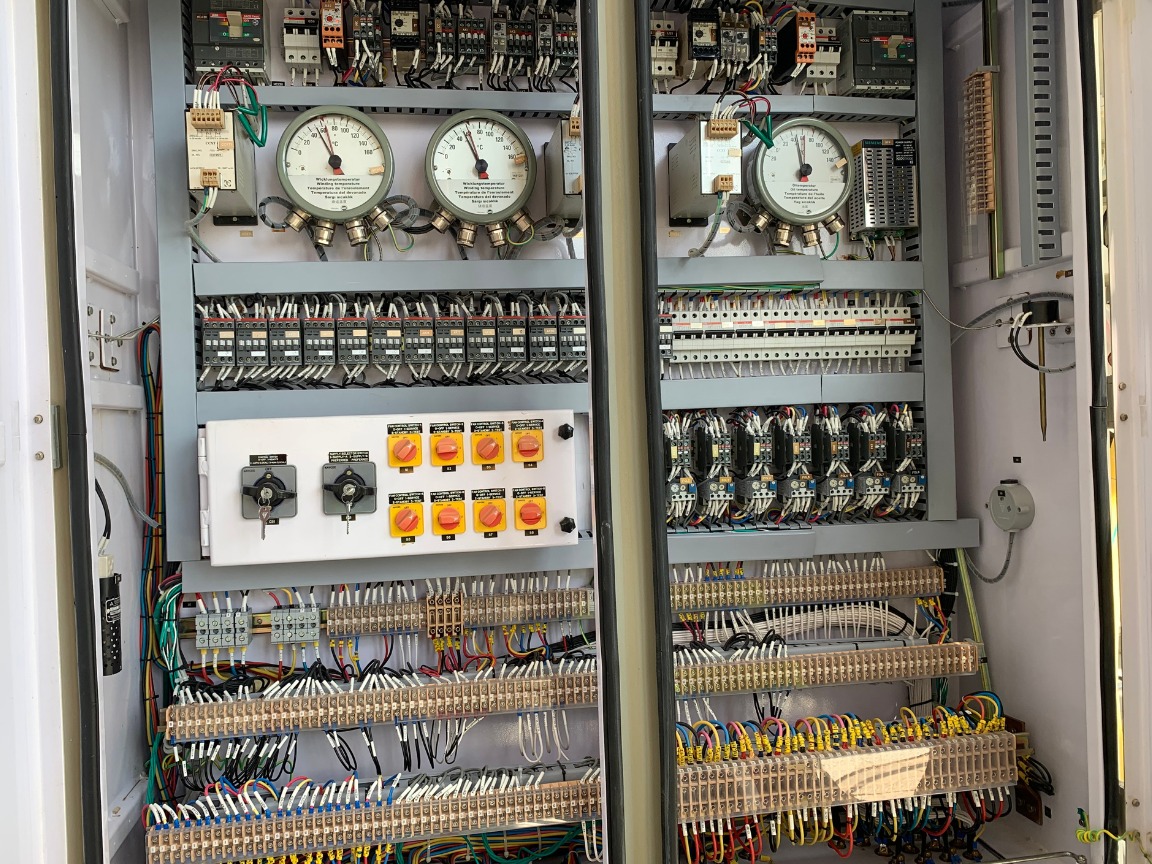

Electrical Tests

- Turns Ratio Test (TTR)

- Winding Resistance Test

- Insulation Resistance Test (Megger Test)

- Dielectric Absorption Ratio (DAR) and Polarization Index (PI)

- Power Factor (Tan Delta) Test

- On Partial Discharge (PD) Measurement

- Sweep Frequency Response Analyser Test

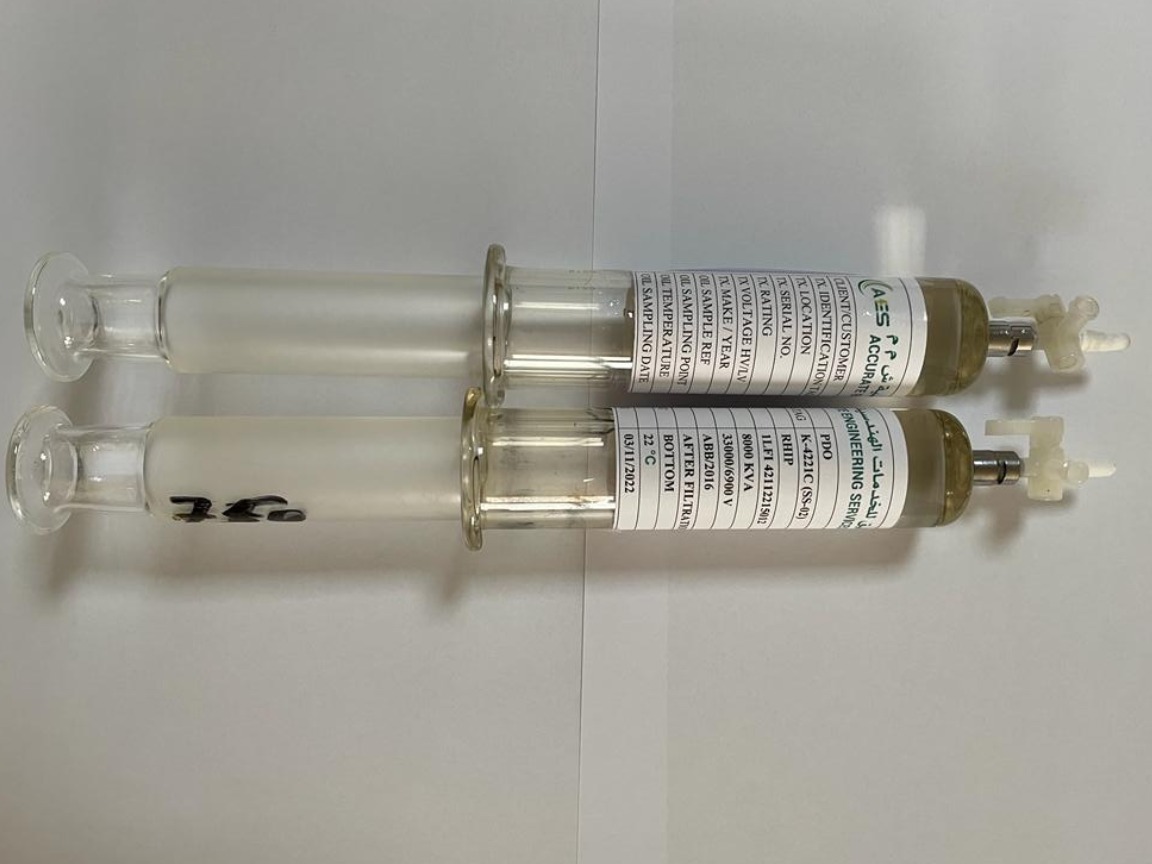

Oil Analysis

- Dissolved Gas Analysis (DGA): Detects gases (e.g., hydrogen, acetylene) indicating potential faults like arcing, overheating, or partial discharge.

- Oil Quality Test: Assesses dielectric strength, acidity, and moisture levels

- Furan Analysis: Evaluates paper insulation degradation.